Human Capital

Managing Occupational Safety and Health

Click to jump to the corresponding section in this page

Konica Minolta's Approach

Background and Issues

Workplace accidents put employee safety at risk. They can also affect the neighboring environment, and if serious enough, they can threaten business continuity. Konica Minolta recognizes that preventing workplace accidents and creating workplaces where employees can work safely and confidently is a critical management issue.

Vision

Konica Minolta believes that the foundation of corporate management lies in the maintenance and promotion of workplace safety and health for every employee. The company aims to build a healthy, safe and supportive workplace environment by implementing occupational safety and health initiatives that emphasize daily preventive actions.

Key Measures and KPIs

Preventing Occupational Accidents

| KPI | Results | Targets | ||||||

|---|---|---|---|---|---|---|---|---|

| FY 2020 |

FY 2021 |

FY 2022 |

FY 2023 |

FY 2024 |

FY 2024 |

FY 2025 |

FY 2030 |

|

| Serious accidents*1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

Note:*

1. Serious accidents:

(1) Death, disease requiring a long recovery period (or the possibility thereof), an injury resulting in a disability (or the possibility thereof), or a specific contagious disease

(2) An accident resulting in the death or injury of three or more workers during work at one point or the contraction of a disease (including accidents not accompanied by lost worktime)

Improvement of the Frequency Rate of Lost-Worktime Injuries

Frequency rate of lost-worktime injuries* in the three-year period of the Medium-Term Business Plan:

FY2020–2022: Reduce to 0.15 or less by Fiscal 2022

(By backcasting from a goal of 0.1 or less by 2030, a new plan was prepared and a revised target value was set.)

FY2023-2025: Reduce to 0.10 or less by 2025

| KPI | Benchmark by FY2022 | Results | Targets | |||||

|---|---|---|---|---|---|---|---|---|

| Average in FY2017-2019 |

FY 2020 |

FY 2021 |

FY 2022 |

FY 2023 |

FY 2024 |

FY 2024 |

FY 2025 |

|

| Frequencyrate of lost-worktime injuries* | 0.23 | 0.17 | 0.19 | 0.18 | 0.12 | 0.22 | 0.12 | Less than 0.10 |

- *

- Frequency rate of lost-worktime injuries: The number of persons absent from work per one million total actual working hours for current employees

See also Social Data (Excel) in ESG Data for information on previous years.

Occupational Safety and Health Management System

The Konica Minolta Group has established the Board of Director-approved Konica Minolta Group Charter of Corporate Behavior to embody the Konica Minolta Philosophy, which consists of Our Philosophy and management vision. The Group is promoting occupational health and safety initiatives and activities based on the Konica Minolta Occupational Safety and Healthcare Policy, which is linked to the Charter.

The Occupational Safety and Health Management Regulations, established in accordance with this Konica Minolta Occupational Safety and Healthcare Policy, aim to ensure the health and safety of everyone working in the Group (officers, employees, contract employees, employees dispatched from an agency, and part-time employees) as well as on-site contractors (including subcontractors and commissioned service providers working within Group premises.

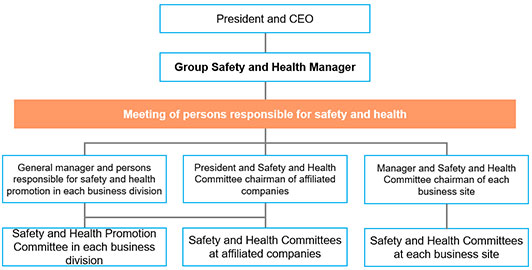

The Konica Minolta Group's safety and health management system is shown in the figure below. Appointed by the President and CEO of Konica Minolta, the Group Safety and Health Officer recommends the appointment of the persons responsible for safety and health promotion in each business division, as well as the Safety and Health Committee members at each site. Group meetings of persons responsible for safety and health, including an industrial physician, are held, and policy decisions and progress checks are made on measures to promote health and safety. In addition, the Group Safety and Health Manager regularly performs internal audits of activity plans and progress at each site and group company, when necessary, such as after an accident, and provides instructions for improvement.

Each site in Konica Minolta Inc. and the Group companies in Japan has established a joint labor-management Safety and Health Committee that meets once a month as an organization to promote enhancement of occupational safety and health. The committee is composed of, in accordance with the law, a general health and safety manager, a safety manager, a health manager, and an industrial physician as well as members from the Company and labor union. Half of the members are appointed based on the labor union's recommendations or as representatives of the workers, and they participate in activities and discussions together with the Company’s committee members. In addition, safety and health management in business promotion is carried out in the form of a Safety and Health Promotion Committee in each business division. When major safety and health problems or concerns are identified, they are reported immediately to the Group Safety and Health Manager and instructions for correction and countermeasures are issued to the Group Safety and Health Management Secretariat. The Secretariat considers/examines the content and works with the relevant division to implement it and then disseminate it throughout the Group.

In addition, the Company has a complaint handling system concerning occupational health and safety. The system involves the Safety and Health Committees and the Safety and Health Promotion Committees interviewing employees concerning incidents, information concerning defects and improvement proposals. The Company has also set up a contact point that serves as a Safety Suggestion Box for receiving queries by direct email to the manager and the person in charge of safety management. When a query is received via the Safety Suggestion Box, we confirm with the inquiring party about conducting an investigation and sharing information about their query, and the results of and response to the query, and limit the sharing of information so that it poses no disadvantage to the inquiring party. Approximately 50 people across the entire Group are engaged as full-time staff for occupational safety and health.

Konica Minolta Group Occupational Safety and Health Management System

All group companies in Japan and the Group’s main production companies outside Japan have adopted an occupational safety and health management system. Some group companies have obtained external certification, ISO 45001. Even companies that have not obtained external certification run and manage safety and health activities in line with their own systems based on the Ministry of Health, Labor and Welfare’s Guidelines on Labor, Safety and Health Management Systems, which comply with the ILO Guidelines on occupational safety and health management systems. Of the entire group worldwide, four companies have acquired external certification, representing 15% of the total number of employees (as of March 31, 2025).

The management system targets employees, including temporary employees, but Konica Minolta asks that subcontractors stationed on site and contractors cooperate with safety and health activities through regular safety and health liaison meetings held by site health and safety committees.

Legal compliance management for management systems covers the following Japanese laws and regulations: the Industry Safety and Health Act and related regulations (Ordinance on Industrial Safety and Hygiene, Ordinance on Health Standards in the Office, Ordinance on the Prevention of Organic Solvent Poisoning, etc.), the Labor Standards Act and related regulations (Ordinance of Labor Standards for Women), and other safety and health-related laws (Fire Defense Law, High Pressure Gas Safety Act, Poisonous and Deleterious Substances Control Act, etc.).

| Company | Date | Valid through | Standard |

|---|---|---|---|

| Konica Minolta Business Technologies (Dongguan) Co., Ltd. | Aug. 13, 2020 | Nov. 27, 2027 | ISO45001:2018 |

| Konica Minolta Opto (Dalian) Co., Ltd. | Dec. 8, 2020 | Dec. 7, 2026 | ISO45001:2018 GB/T45001-2020 |

| Konica Minolta Business Technologies (Malaysia) Sdn. Bhd. | Jan. 16, 2015 | Jan. 15, 2027 | ISO 45001:2018 |

Preventing Accidents During Working Hours

Strengthening and Continuously Carrying Out Risk Reduction Efforts to Prevent Occupational Accidents

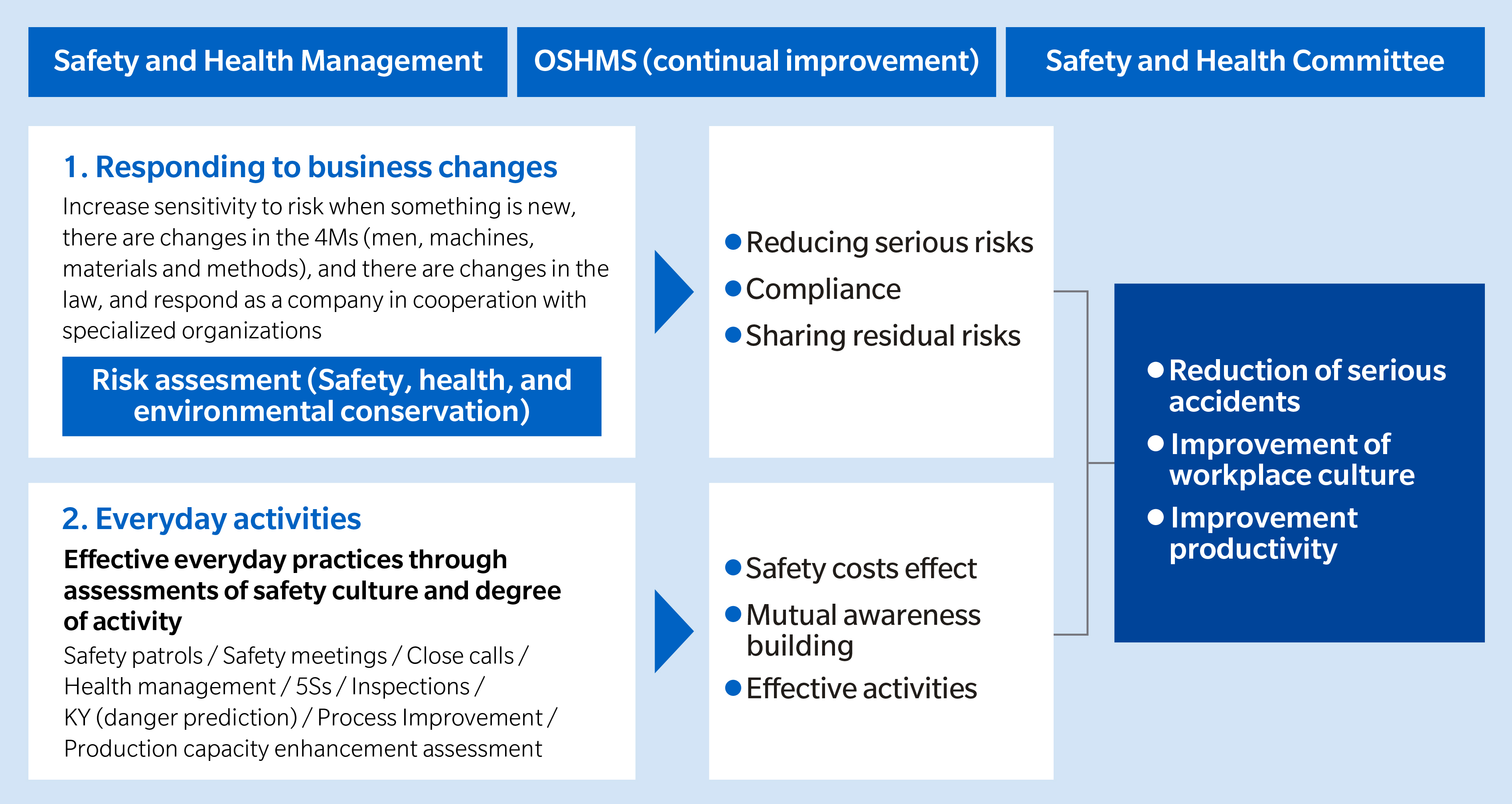

During the three-year period of the Medium-term Business Plan (FY2023–2025), the Group will implement a variety of measures to prevent accidents from occurring during working hours, with the goal of reducing the frequency rate of lost-worktime injuries to 0.10 or less by 2025. With the occupational safety and health management system (OSHMS) and the organization of safety and health committees serving as the cornerstones, the Group works through the PDCA cycle, focusing on risk assessment to deal with business changes and daily activities such as safety inspections and sharing information about near-miss incidents.

Konica Minolta’s Safety and Health Initiatives

All workplace accidents within the Konica Minolta Group must be reported and recorded in the accident database system within 24 hours, and the information is then shared internally.

In fiscal 2024, there were no serious accidents.*1 However, there were 10 accidents causing absence from work. The frequency rate of lost-worktime injuries*2 was 0.32 in Japan and 0.06 outside Japan, for a total of 0.22. The severity rate of accidents causing absence from work*3 was 0.0034 in Japan and 0.0029 outside Japan, for a total of 0.0032.

Konica Minolta has maintained a lost-time injury frequency rate below the average for similar industries. According to the Ministry of Health, Labour and Welfare's Survey on Industrial Accidents the average lost-time injury frequency rate for domestic manufacturing in fiscal 2024 was 1.30, while for the electrical machinery and equipment manufacturing industry, it was 0.67. Despite this, the Company did not meet its internal safety target (KPI).

The primary reason for not achieving the target was an increase in fall-related accidents among employees aged 50 and over, and a rise in their severity of these injuries. In response, Konica Minolta will enhance safety awareness through age-specific safety training and simple physical fitness tests.

The Konica Minolta Group conducts risk assessments when making changes to facilities, chemical substances, personnel, or procedures and through these assessments it has identified priority risks with a high risk of serious consequences such as fires or explosions caused by flammable substances, dust, or electrical accidents, and being caught or entangled in the moving parts of machinery or equipment. Konica Minolta takes measures to prevent workplace accidents based on an action plan, and as a result, of the ten accidents causing absence from work in fiscal 2024.

- *1

- Serious accidents:

1. Death, disease requiring a long recovery period (or the possibility thereof), an injury resulting in a disability (or the possibility of a disability thereof), or specific contagious diseases

2. Accidents that cause three or more employees at one time to suffer on-the-job death, injuries or diseases (including accidents that do not cause absence from work) - *2

- Frequency rate of lost-worktime injuries: The number of persons absent from work per one million total actual working hours for current employees

- *3

- Severity rate of accidents causing absence from work: The total number of days absent from work per 1,000 total actual working hours for current employees

See also Social Data (Excel) in ESG Data for information on previous years.

Providing Safety Training

The Konica Minolta Group conducts grade-specific employee education both in Japan and overseas. Safety training is provided for all employees at the time of recruitment or task modification, as well as safety training for newly appointed assistant managers and managers, respectively.

In each workplace, the Company provides necessary training including the development of chemical substance managers and supervisors responsible for ensuring the proper use of protective equipment. It also conducts hazardous materials safety training based on the Fire Service Act, as well as training on high-pressure gas safety and machinery and equipment safety. In addition, safety training is also given for especially high-risk work, covering topics such as the prevention of fires, explosions, and forklift accidents.

Safety Mindset Refresh Education

Beginning in fiscal 2017, Konica Minolta began offering a short (five minutes per session) “refresh” course to remind employees to be aware and take the initiative to take personal responsibility for their own safety, and the Company continues to provide this training. In fiscal 2024, this “refresh” course was given in a monthly e-learning format to around 9,200 employees of Konica Minolta, Inc. and Group companies in Japan as well as expatriate staff, with 95% of employees completing the course.

Overseas production companies share information on accidents that have occurred in the Group using materials that have been translated into English and Chinese. Countermeasures are carried out for every issue to prevent accidents from occurring. In addition, companies also provide education based on video materials―case studies on accidents that have occurred in the Group created by the safety personnel―as part of the sites’ ongoing efforts to raise safety awareness.

Hazard Simulation Education

To proactively prevent accidents, the Company has implemented hazard experience training since fiscal 2014. This program uses equipment that simulates the dangers of being caught or pinched by rotating and movable machinery allowing employees to experience the fear of such accidents. Initially rolled out in overseas production sites, it expanded to domestic sites in fiscal 2017 and was implemented across all domestic production sites by fiscal 2018. In fiscal 2019, in addition to continuing this training, the Company launched a virtual reality (VR) experience training program for hazard simulation. Since fiscal 2021, this program has also been extended to production factories in China and Malaysia, following its introduction in Japan.

Strengthening Safety Management

Strengthening Safety Management through the Konica Minolta Group’s Globalization and by Responding to Business Changes

Accidents Involving Explosions at Konica Minolta Supplies, Inc.

On July 6 and August 12, 2021, dust explosions occurred at the Tatsuno Plant of a Group company, Konica Minolta Supplies. Although no employees were injured nor any other casualties reported, the accidents caused inconvenience to the many people concerned, including impacts on local community safety and on product supply. As a result of an investigation that included objective advice from a third-party organization, it was determined that the dust explosion was most likely caused by static electricity generated in the secondary drying process in the toner production process. A risk assessment was conducted by experts, including at the company's Kofu Plant, which uses a similar process, and production was resumed after switching to a new production process.

Strengthening Risk Assessment (Reviewing System and Structure)

Since fiscal 2016, the Group has developed and continued a company-wide system to conduct risk assessments when new equipment, chemical substances, personnel or procedures are introduced or when 4M changes are made. These are conducted from a comprehensive perspective, including employee safety and health, fire and explosion accidents, and environmental impact.

However, since the two explosions mentioned above occurred, the Group analyzed the situations, down to the root causes. As a result, the Group concluded that it was necessary to eliminate omissions in the identification of risks and their variables, and that strengthening risk assessment was the key to achieving this. In order to prevent major fires and explosions from ever occurring again within the Group, as a specific action, we substantially revised the Occupational Safety and Health Management Regulations in fiscal 2022 based on the opinions of experts inside and outside the Group. In the revision, we set for the system, responsibility, and authority for risk assessment such as that it be conducted by the relevant business division or affiliate. In addition, we established detailed risk assessment regulations to define the rules and procedures for conducting risk assessments. In fiscal 2022, business divisions and affiliates played a leading role in promoting risk assessments in line with the rules and procedures.

Furthermore, we conduct ongoing systematic risk assessments not only when new equipment has been installed or when 4M changes are made, but also for existing equipment and operations.

Safety Management Using Unsafety Marks

In fiscal 2017, the Konica Minolta Group adopted “Unsafety Marks” as a new safety management indicator tailored to Konica Minolta's business operations. It was created with reference to the best practices of leading manufacturers in terms of safety. Each accident including not only those causing absence from work but also those not causing absence from work, commuting accidents and even fires and explosions, is assigned a numerical value based on the type and severity. The values for all the accidents are then totaled to obtain a score for the safety level of a site. Low Unsafety Marks indicate a high level of safety. The purpose is to use this indicator to identify and analyze the causes of accidents, in order to help prevent accidents from occurring or reoccurring.

The Group as a whole has managed its safety performance based on targets set under the new three-year plan, achieving a score of 164 points in fiscal 2024, 8% lower than the previous year’s score of 178 points.

Creating a Culture of Safety

For employees to feel fulfillment in their work and demonstrate creativity and originality, it is important that we create a workplace where employees can work without accidents and in safety. To achieve such an environment, the Konica Minolta Group believes that it must build a culture where “safety takes priority over everything else” and it will pursue the following three initiatives to build a culture of safety during the medium-term business plan starting in fiscal 2023.

1. Strengthen professional safety: Steadily reduce accident risks stemming from workplace hazards and dangers through enhanced risk assessment

2. Promote universal safety: Provide a multifaceted education to prevent accidents that could occur anywhere in life, such as falls.

3. Promote group safety activities: Support and audit the safety of domestic and overseas subsidiaries and affiliates.

Since fiscal 2023, we have designated July 6, the date of the first accident, as Safety Day in order to keep the memory of the explosion that occurred at the Tatsuno Plant of Konica Minolta Supplies Manufacturing Co., Ltd. alive and to promote accident prevention efforts. On Safety Day, members of senior management visit production sites in Japan to check the workplace environment, accident risks, and safety initiatives with those who work onsite, and think together about how to create a safe workplace. Through these efforts, together with employees, we will build a culture where safety takes priority over everything else under the slogan of “Safety First,” create a workplace where employees can work safely without accidents and strive to be a company that prides itself on safety.