Konica Minolta’s Environmental Activities

Production Activities to Solve Environmental Issues

(Green Factory Certification System)

Background and Issues

As environmental problems become increasingly serious, society requires greater energy efficiency, the use of renewable energy, and more efficient use of limited resources. Reducing environmental impact in the production process, especially in the manufacturing industry, has a significant effect on reducing the impact of society as a whole, and therefore, achieving substantial reductions is considered important.

Vision

Konica Minolta streamlines production processes, develops and improves production technologies, and takes steps to reduce its environmental impact while cutting costs.

Konica Minolta carries out Green Factory activities at its manufacturing sites, and also implements highly effective reduction measures, such as energy conservation activities, effective use and recycling of resources, and the introduction of renewable energy.

Key Measures and KPIs

Reduction of environmental impact of Konica Minolta production sites utilizing the company’s own know-how and cutting-edge environmental technologies

(Unit: thousand tons)

| KPI | Results | Targets | |||||

|---|---|---|---|---|---|---|---|

| FY2020 | FY2021 | FY2022 | FY2023 | FY2024 | FY2024 | FY2025 | |

| Reduction of CO2 emissions at Konica Minolta production sites through energy-saving activities | 4 | 12 | 18 | 8* | 18 | 17 | 21 |

| CO2 reduction through the introduction of renewable energy | 7 | 10 | 20 | 3 | 14 | 13* | 55 |

| Reduction of waste discharge at Konica Minolta production sites | 0.6 | 1.3 | 1.7 | 1.6 | 2.1 | 1.6 | 1.7 |

Note:

The figures represent the cumulative reduction effects during each mid-term plan period from FY2020 to FY2022 and FY2023 to FY2025. The reduction effects of measures implemented from the first year of each period to the relevant fiscal year are summed for each fiscal year. Targets for FY2024 and FY2025 have been revised based on FY2023 results.

* Figures for FY2024 were revised due to errors found in the disclosure.

Initiatives in Production

Konica Minolta has long promoted green-factory activities at its in-house production sites to simultaneously reduce its environmental impact and lower costs. The Company is implementing a Green Factory Certification System, which requires that production sites meet two standards: environmental impact reduction standards to evaluate energy and resource conservation measures, and guideline standards to evaluate the quality of activities.

The certification system targets sites that have a large impact on Konica Minolta’s total environmental load (energy consumption and external emissions). It also targets business units, production sites, or development sites where reducing environmental impact (such as lowering the carbon footprint) can be a competitive indicator in a business environment or based on customer requests.

To meet the guideline standards, it is necessary to fulfill all 12 items that reflect growing social and environmental expectations. These include building systems for environmental activities and training, identifying and implementing measures for energy and resource conservation and renewable energy use, and managing water resources.

By promoting initiatives to meet two standards at its production sites, the Company aims to enhance its contribution to the global environment and accelerate efforts to address social issues.

| Material-based production sites | Assembly based production sites | ||

|---|---|---|---|

| Environmental Impact reduction Environmental impact reduction standards to be achieved by Konica Minolta production sites |

CO2emissions | 3% reduction annually through energy conservation (9% over 3 years) |

2% reduction annually through energy conservation activities (6% over 3 years) |

| Ratio of electricity from renewable energy sources | Set for each site (e.g., 100% achievement, 20% introduction) | ||

| Waste discharge | 2% reduction annually (6% over 3 years)* |

2% reduction annually (6% over 3 years)* |

|

| Guideline Standards for environmental management initiatives to be pursued by Konica Minolta production sites |

Guideline compliance status | Complying with guidelines on items such as:

|

|

Note:

This applies to major production sites that have a large environmental impact on Konica Minolta and are deemed a priority in the medium-term business plan.

* This target includes efforts to reduce plastic waste at major sites in Japan, in line with activities to curb and recycle industrial waste from plastic products, based on the Act on Promotion of Resource Circulation for Plastics enacted in Japan.

Results of Activities to Date

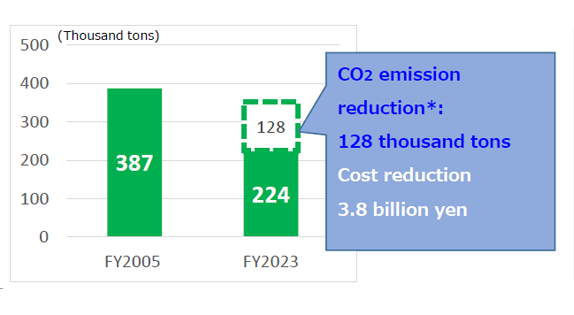

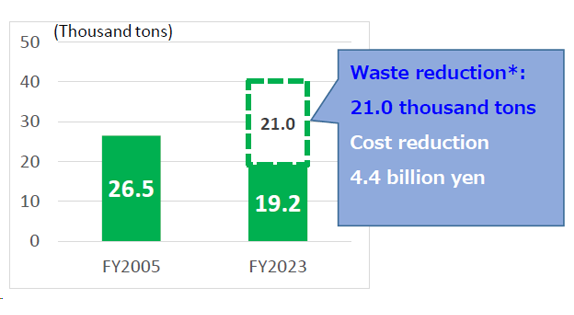

Since the 2000s, Konica Minolta has actively promoted Green Factory initiatives, implementing a wide range of measures to reduce CO2 emissions and waste output, while simultaneously achieving cost reductions.

The cumulative reductions achieved through initiatives implemented since the launch of Green Factory activities in fiscal 2005 are as follows.

CO2 Emissions Reduction Effect during Production*

* Reduction in emissions from the estimated amount if no measures are taken.

For details on specific reduction initiatives, please refer to the following:

Addressing Climate Change > Promoting Decarbonization in Production

Waste Reduction Effect during Production*

* Reduction in emissions from the estimated amount if no measures are taken.

For details on specific reduction initiatives, please refer to the following:

Building a Recycling-Oriented Society > Resource Conservation and Recycling in Production Operations