News Releases

Konica Minolta Launches the CA-527, a Next-generation Display Color Analyzer Offering Industry-leading Ultra-low Luminance Measurement and High SpeedQuickly Meeting the Needs of Development and Production Sites of Evolving Next-generation Displays

March 19, 2024

Tokyo (March 19, 2024) - Konica Minolta, Inc. (Konica Minolta) today announced the launch of the CA-527, a color analyzer that meets the needs for evaluating ever-evolving cutting-edge displays, such as OLEDs and microLEDs.

The CA-527 is an optical measuring device used for inspection and adjustment of white balance,*1 gamma,*2 and flicker*3 at sites that develop and produce displays for TVs and smartphones, among others. This is the latest flagship model of the Display Color Analyzer series, which is reputed for its high-speed, accurate measurement.

In line with the rapid evolution of the display industry in recent years, there have been growing needs among developers and producers for faster, more accurate measuring devices with capabilities in even lower and higher luminance ranges.

The CA-527 offers industry-leading*4 low luminance measurement and high speed. The application function has also been enhanced in line with the technology trend of cutting-edge displays. The product meets the latest evaluation needs of high-resolution next-generation displays, such as increasingly higher-dynamic-range (HDR) OLEDs and microLED displays.

Value Provided by the CA-527 Display Color Analyzer

1. Further expansion of the accuracy-guaranteed luminance range

Compared to the conventional CA-VP427A model, the measurement dynamic range has been expanded to cover from 0.0001 cd/m2, which is one third the brightness in low luminance, up to 10,000 cd/m2, which is twice the brightness in high luminance. The CA-527 guarantees the measurement accuracy and repeated measurement performance over a wider range, meeting the need for more accurate evaluation of luminance*5 and chromaticity*6 of high-resolution next-generation displays, such as OLEDs and microLEDs, with their ever-higher contrast ratio and wider color gamut.

2. Increase in measurement speed

Thanks to the state-of-the-art optical design, the CA-527 significantly reduces the measurement time at low luminance in particular compared to the conventional Color Analyzer series. This is not only useful for R&D on displays but also reduces the takt time*7 during the manufacture of displays.

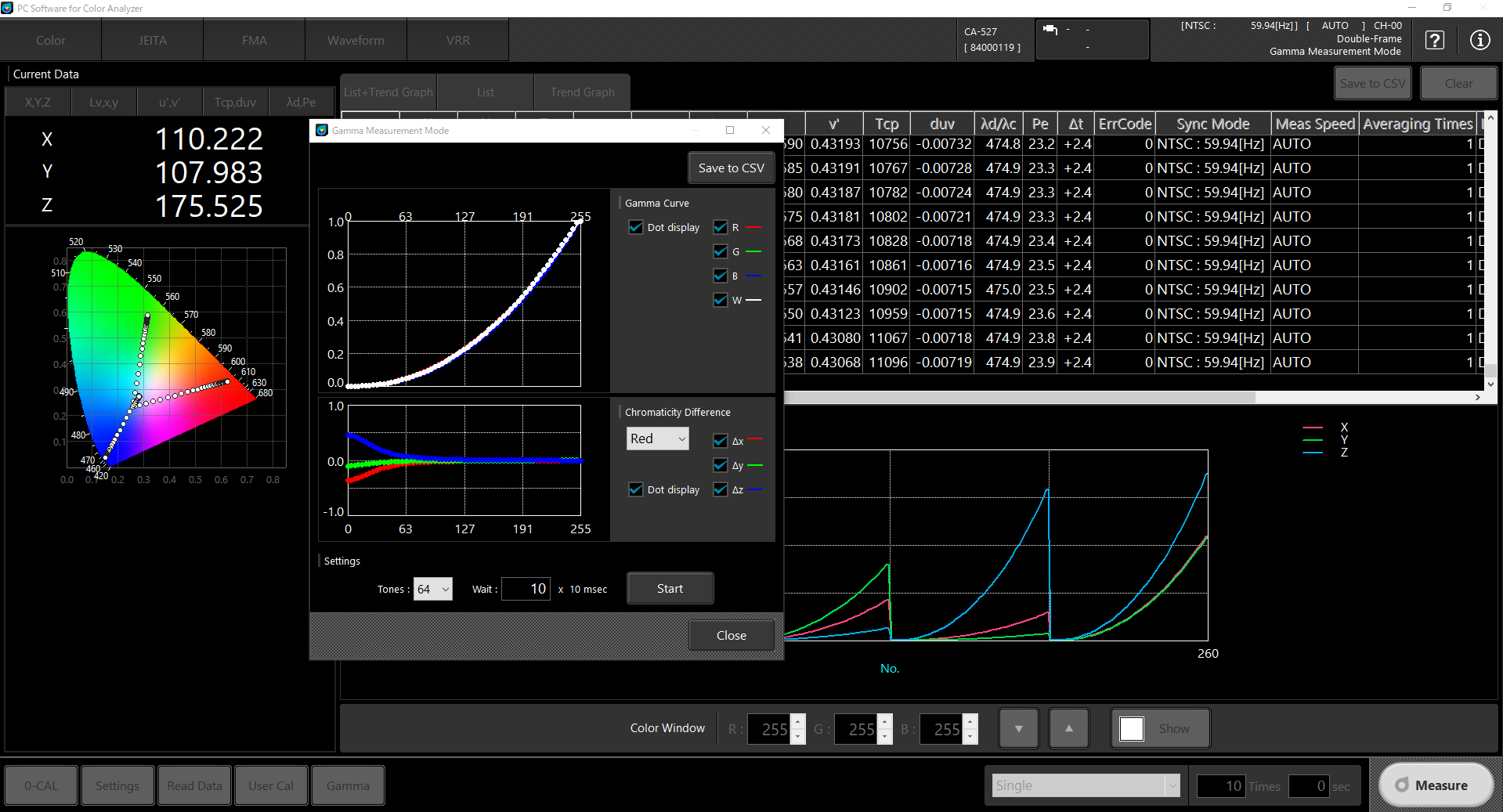

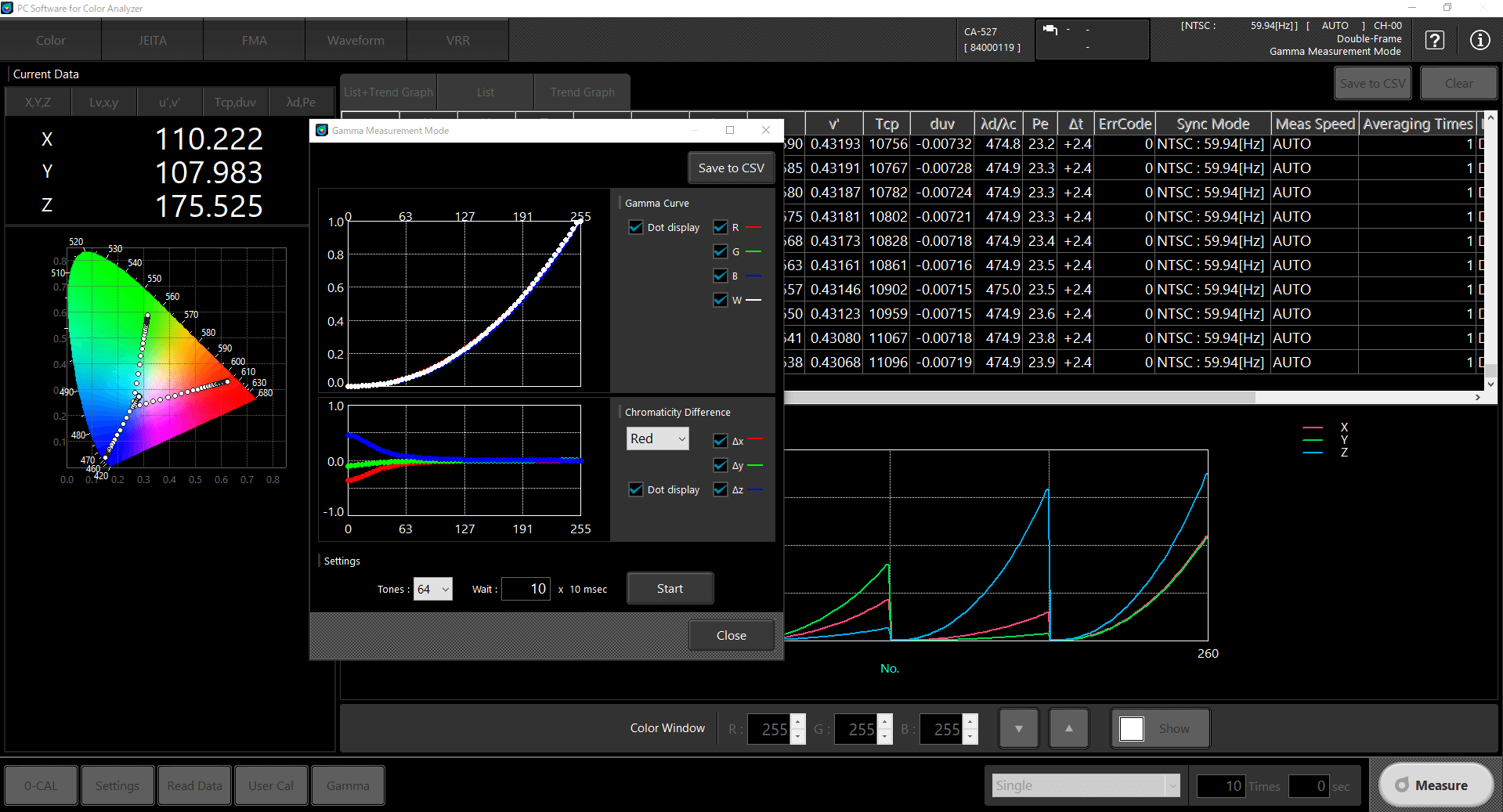

3. Enhancement of the application function*8 that meets the technology trend of cutting-edge displays

1) Significant performance improvement of the display light-emitting waveform measurement function

Compared to the conventional Color Analyzer series, the CA-527 can conduct measurement in the lower luminance ranges at higher sampling frequencies. This can more accurately determine the display light-emitting waveforms, which are becoming increasingly complex, in line with the recent trend of display development technology, including OLED displays, toward higher contrast ratio, and cutting-edge microLED displays, which use the time-sharing drive method.

2) New implementation of the variable refresh rate (VRR) flicker measurement function

The function to measure the flicker that could be caused by the variable refresh rate (VRR), which is becoming a standard feature of cutting-edge displays, has been newly implemented in addition to the high-performance flicker measurement function, including the JEITA method offered by the conventional Color Analyzer series. The CA-527 aims to become the new de facto standard with industry-leading*4 flicker measurement performance for evaluating the quality of the latest displays which offer higher video quality and consume less power.

Main Specifications

| Luminance | Accuracy-guaranteed range | 0.0001 to 10,000 cd/㎡ |

|---|---|---|

| Accuracy (for white)* | > 0.0001 cd/m2: ±9% > 0.001 cd/m2: ±2% > 0.01 cd/m2: ±1.5% |

|

| Chromaticity | Accuracy-guaranteed luminance range | 0.001 to 10,000 cd/m2 |

| Accuracy (for white)* | > 0.001 cd/m2: ±0.003 > 0.01 cd/m2: ±0.002 |

|

| Accuracy-guaranteed measurement speed (AUTO) |

Lvxy | > 0.0001 cd/m2: 1 time/sec > 0.015 cd/m2: 5 times/sec > 0.2 cd/m2: 20 times/sec |

| Interface | USB 2.0, RS-232C | |

* Measured under Konica Minolta’s standard light source (6500K)

About Konica Minolta's Sensing Business

Konica Minolta's Sensing Business offers various products and solutions in the fields of light source color measurement and object color measurement based on the optical technologies developed in its former camera business and continually refined thereafter. The products and solutions offered by Konica Minolta contribute to ensuring quality and improving productivity at customers' manufacturing sites, and many products are used as de facto standard color measurement instruments. Notably, Konica Minolta has more than a 50% share in the global market for display image quality measurement and inspection (estimated by Konica Minolta), and has a solid presence as the market leader.

Konica Minolta has actively promoted investments to strengthen its competitiveness. In 2012, the Company acquired Instrument Systems GmbH (Germany) which develops high-end optical measuring instruments and has an outstanding track record in the high-performance measurement of displays and LED lighting devices. In 2015, the Company acquired Radiant Vision Systems, LLC (U.S.) which excels at high-resolution 2D measurement instruments for displays, image processing software, and automatic appearance inspection systems. In 2019, the Company acquired Eines Systems (Spain), a market leader in the field of visual inspection of automobiles. In 2020, the Company acquired Specim, Spectral Imaging Ltd. (Finland), a leading company in the field of hyperspectral imaging (HSI*9).

In the Industry Business, including the sensing business, Konica Minolta’s development, manufacturing, and customer support have come together to co-create value by building strong relationships with customers with core technology as its strength. The Company has set the fields it will focus on in the future as “display,” “mobility,” and “semiconductor manufacturing,” strategically invest mainly in the strengthening businesses of sensing, performance materials, IJ components, and optical components (industrial applications), and promote business development that is more closely linked to the customer’s manufacturing value chain.

*1:White balance is the process of adjusting the light intensity ratio of light in the three primary colors - red, green, and blue – for accurate reproduction of white.

*2:Gamma is a measure of tonal response. Gamma correction makes the brightness and color of the black and white halftone appear more natural and smooth to the eye.

*3:Flicker is a visible change in brightness on a display. Physically, it is the blinking or fluctuation of light. Flicker also refers to a state that can be perceived by the human eye. Because the human eye cannot observe high-frequency phenomena, flicker may be evaluated by taking into account the frequency characteristics of sensitivity.

*4:As a luminance colorimeter of the photoelectric tristimulus colorimetry type as of March 14, 2024

*5:Luminance is the quantified brightness per unit area of light emitted from the light source. It is the psychophysical quantity of brightness perceived by individuals. In the International System of Units, the unit is candela per square meter (cd/m2).

*6:Chromaticity is the quantified color of the light source perceived by individuals. The most typical evaluation index is the XYZ color space (CIE 1931) defined by the International Commission on Illumination (CIE) in 1931.

*7:Takt time is the operating time required until one product is manufactured in the production process. Reducing the takt time improves production capacity, and thus generally reduces cost.

*8:The application function is used by users depending on the purpose.

*9:HSI is a method that uses a camera with narrow bandwidth over a wide spectral range from the visible to mid-infrared wavelength region to identify substances in an area. It is expected to be used for applications such as recycling, material/resource identification, food analysis, environmental safety, product surface condition analysis, etc.

*Product names and other names indicated in this news release are registered trademarks or trademarks of each company.

Correction: April 1, 2024

At the original publication on March 19, 2024, the item "Display range" was included in the Main Specifications. Because it is not necessary for this product, ”Display range” has been deleted.